As building envelope consultants, SOCOTEC has provided expert advice across numerous continents for over 30 years, assisting clients in determining their project goals and requirements within their fiscal budget in order to ensure the finest enclosure system for their project.

Envelope Consulting

Facade systems are an opportunity for architectural expression, sustainability and reduction of energy usage in the built environment. SOCOTEC can be integrated into the designer’s process to fully understand the design vision and goals for the project from early design through construction administration.

SOCOTEC maintains the highest quality standards of design and installation of the walls, foundation, roof, doors and glazing to ensure that they produce a durable enclosure system. These systems present a great opportunity for architectural expression, sustainability and energy reduction in the built environment. Our consulting services ensure enclosure systems intelligently respond to factors of light, radiation, load, pressure, wind, acoustics, motion, temperature differentials (expansion and contraction), and moisture. The building envelope must function as a barrier, mitigating potential damages and producing healthy, comfortable and sustainable indoor environments. Our experienced staff ensures that each component is properly designed, assembled and installed into a robust building envelope system.

Talk to our experts

Curtain Wall Consulting

SOCOTEC’s expertise in curtain wall consulting is unmatched with a host of repeat clients and a portfolio of monumental projects located around the globe. Our long track record spans back to the 1980’s with projects like Canary Wharf and Petronas Towers; today, we continue to work on the highest performing towers, like 1 Vanderbilt, the Hub on Causeway, and Paramount Miami Worldcenter.

Our project portfolio includes the curtain wall facades of some of the tallest buildings in the world, the first LEED Platinum office tower in the US, several institutional double wall curtain walls, many commercial reclad office towers, and the largest installation of dynamic-glazed integrated curtain wall and triple IGU-glazed curtain wall in the United States.

We work closely with Design Architects to help forge and realize their vision for the façade with optimization studies, detail development, practical commercial guidance and proven solutions from past projects. Our team helps create the basis of design sets of details for pricing using cutting-edge software and refines an appropriate performance specification to meet each project and each client’s needs.

We have very deep relationships with curtain wall fabricators on four continents and guide our client to them through the procurement process. Where the curtain wall is custom, we roll up our sleeves during the Design Assist process, post-award, to achieve the most efficient design while staying within budget and getting to a successful Visual and Performance Mock-up faster. Our review of details on shop drawings are rooted in a practical approach and backed by experience. The majority of our curtain wall consultants started in the field and in shops inspecting and understanding how curtain walls are put together.

We have developed an efficient internal QA/QC process that ensures a consistent approach to communication, issue recognition, and faster resolution. It is a digital feedback loop that connects each project, each staff member and the years of experience together to provide unrivaled service.

We are all over the world in glass and curtain wall shops witnessing first article and routine unit assembly, the mock-up installation in a test chamber and each rigorous mock-up test. We are problem solvers at heart. We are most in our element at the laboratory investigating and solving unforeseen issues during mock-up testing.

We have a balanced commercial and technical approach and understand how international supply chain issues, different standards and expectations for quality can impact a curtain wall façade. Our experienced bench of shop and site (special in NYC) inspectors ensure the project’s curtain wall quickly progresses vertically, maintains the highest level of quality and that the entire team benefits from our proactive solutions and stay informed via daily communication, both verbal and via exceptionally comprehensive reports.

In short, we are an integral part of the curtain wall consulting industry every step of the way and are solidly placed to help in the next generation of this façade typology on the simplest to the most challenging projects to help the team ensure a successful outcome.

Cladding

Cladding are most often grouped into manufactured materials, natural materials or a hybrid. Our in-house experts can help in the selection, specifying and integration of established or innovative cladding systems, no matter their origin.

Metal Cladding

Manufactured cladding materials include an assortment of metals such as steel, aluminum and zinc in a range of painted or anodized finishes. Metal materials can be intended to patina naturally as they age gracefully or maintain their original color and gloss over the years. Vidaris has years of experience in sourcing such products from around the world, developing options and guiding our Architects and Developers through a selection process. We have meaningful specification and performance parameters to ensure the right quality material is bought and installed. We have traveled the globe and seen metal cladding systems being fabricated and installed. The supply chain, the differences in standards between countries and sustainability regulations are just some of the challenges that we are very capable of navigating to ensure a fast track delivery to a satisfied client.

Glass Cladding

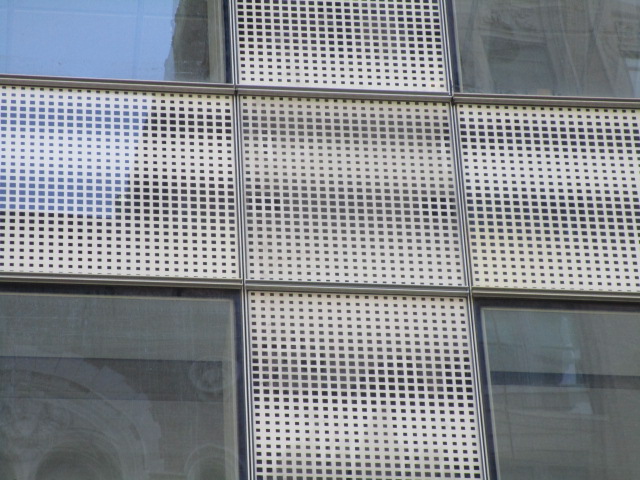

Other opaque materials include glass products such as channel glass, spandrel glass or glass block with opaque or translucent coatings, custom frit patterns and interlayered materials like mesh. The interplay of reflectivity and absorption of light off the glass and patterned surfaces during the day or artificially at night sets the tone of the building. Our experience with visual mock-ups including lighting mock-ups helps our clients ensure that the right effect is achieved.

Stone Cladding

Natural cladding materials include natural stone. We have been involved with some of the largest installation of exterior and interior (lobby) stone installations. Selecting a tried and tested stone or an exotic stone new to the location and environment of a project is something we are familiar and have a process for assessing the pros and cons, opportunities and limitations of. We engage stone experts and laboratories from around the world to help in the petrographic analysis, structural and durability testing and source block sampling processes.

Concrete, Terracotta and Brick Masonry including Precast

Hybrid cladding systems include concrete and simulated stone facades in precast, handset, GFRC as well as terracotta and brick masonry systems used in both hand set and unitized shop installed systems. The versatility of a custom bespoke fabricated façade element using natural materials like clay and stone allows for the cost-efficiency, reliable performance and long-term durability of such systems.

Specialty Structures

SOCOTEC assists designers in the development and execution of complex and abstract structures. We work on all types of projects ranging from skylights, vaulted roofs, suspended structures, complex trusses, porte-cohères and atriums to large, cantilevered assemblies in glass metal and a myriad of other materials.

Our Specialty Structure services include:

- Concept sketch service

- Develop proposed design for general component sizing and materiality

- Perform initial structural analysis

- Perform finite element analysis of proposed design to verify validity of proposed design

- Provide technical specifications and details for proposed systems